CoolRun uses a unique blend of passive refrigeration, patented airflow control, and real-time IoT monitoring to ensure precise temperature regulation for frozen and chilled cargo. By cutting emissions and lowering operating expenses, it sets a new standard in cold chain logistics—safeguarding both your products and your bottom line.

July 3rd, 2025, represented a milestone for CoolRun as we launched the game-changing cold-chain pod at Welch’s transport centre in Duxford.

Bringing together a brilliant mix of people, from policymakers and researchers to customers and logistics pros, for the very first CoolRun Demo Day at Welch’s Transport Depot. It wasn’t just a product launch; it was a real moment of momentum for everyone working to make cold chain logistics cleaner, more innovative, and more sustainable.

Hosted as a partnership between CoolRun and Welch’s Transport, the day focused on big ideas, real-world solutions, and a shared commitment to decarbonising the way we move temperature-sensitive goods.

Introducing CoolRun

We kicked things off with a warm welcome, plenty of coffee, and the first up-close look at the CoolRun Pod. Guests explored visual displays and watched a live cross-docking demonstration as the pod rolled in on one of Welch’s electric vehicles — a powerful way to demonstrate our commitment to real-world innovation.

From there, the morning was packed with fast-paced talks that tackled the big questions CoolRun was built to answer — from cutting emissions to rethinking how cold chain logistics can work smarter.

Cambridge Council: Vision for Sustainable Urban Logistics

Cllr James Rixon, Vice-Chair of South Cambridgeshire District Council’s Climate Change and Environment Committee, delivered a powerful message on the urgent need to decarbonise logistics. He highlighted the sector’s significant carbon footprint, which contributes nearly a quarter of global CO₂ emissions, and praised Welch’s Transport as a leader in driving change.

Rixon emphasised that the path to net zero must run through our freight corridors and last-mile delivery systems, where innovation like the CoolRun Pod offers scalable, low-carbon solutions.

These innovations, he argued, are transforming the way goods move through our cities. His closing message was clear: decarbonising the supply chain isn’t just a climate necessity—it’s a business imperative. The time to act is now.

What’s in the Air? David May Breaks Down the Hidden Costs of Chilled Transport

Our CPO, David May, took the stage to share a compelling research perspective: “Refrigerated Transport & Urban Air Quality.” David brought a crucial angle into focus – air pollution, especially in our towns and cities.

His session broke down the data, showing just how big an impact, these systems can have on urban air quality, and the numbers speak for themselves. More innovative logistics, cleaner technology, and CoolRun innovation are part of the solution, and the numbers show why we need to act fast.

It was a brilliant moment in the day, reminding us that sustainability isn’t just about CO₂ – it’s also about the air we breathe.

Welch’s Transport: Leadership in Action

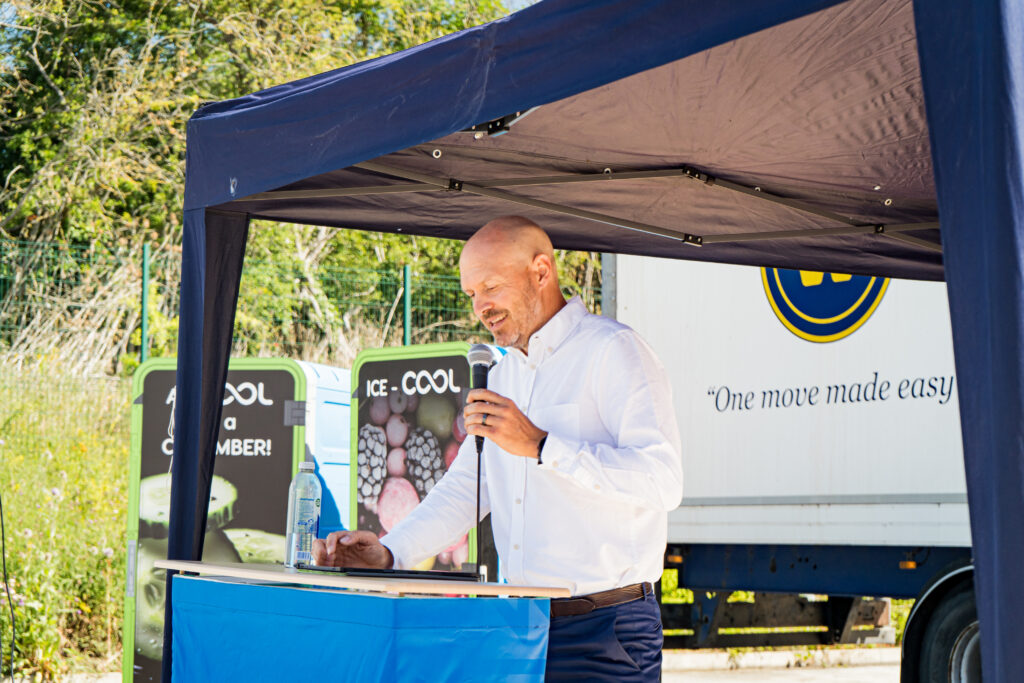

Chris Welch (from Welch Group) shared an honest and inspiring account of Welch’s Sustainable Journey – a company-wide effort to tackle emissions head-on in one of the hardest-to-decarbonise sectors: refrigerated transport.

Chris captured it perfectly: “Refrigerated emissions are a major issue—here’s what we’re doing.”

By analysing their fleet data to identify the areas with the most significant emissions, and by piloting electric refrigeration units and investing in low-emission vehicles, Welch Group is integrating sustainability into the core of its operations.

They’re not waiting for the perfect solution—they’re moving now, learning fast, and sharing that learning with others. This is what leadership in logistics looks like: data-informed decisions, practical trials, and a willingness to do things differently.

CoolRun Pod Showcase: Innovation in Motion

The focal point of the event was the official unveiling of the CoolRun production pod, where attendees were presented with detailed insights into trial performance metrics, funding secured through innovation grants, and the phased roadmap for commercial deployment.

Designed to optimise cold chain operations, the pod delivers a significant increase in payload efficiency while achieving zero direct refrigeration emissions, thanks to its fully electric, eutectic-based thermal management system. This represents a substantial advancement in sustainable refrigerated logistics, combining operational scalability with proven reductions in environmental impact.

Customer Voices: JS Davidson & FastNet Fish

Fastnet Fish shared their journey toward more sustainable cold chain logistics, highlighting both the internal and external pressures driving change across their business. With growing demands to reduce carbon emissions, lower delivery costs, and increase payload, Fastnet saw CoolRun as a solution aligned with their operational goals.

Introduced to the concept through the Cold Chain Federation, they joined the Lincoln University-supported trial programme and quickly invested in testing the pods for their frozen seafood deliveries.

The results were compelling — the CoolRun pods outperformed traditional freezer vans in maintaining sub-zero temperatures by utilising PCM (Phase Change Materials) to stay well below the required thresholds. With confidence in the solution and strong collaboration with the CoolRun team, Fastnet is now planning long-term implementation across its fleet.

Panel Discussion & Q&A

The day concluded with an energetic panel discussion led by Lijo Jose, who opened the floor for speakers and attendees to explore what the future holds. From policy challenges to scaling opportunities, the conversation covered a wide range of forward-looking topics.

Ready to Decarbonise Your Cold Chain?

If you’re looking to reduce your emissions, cut refrigeration costs, or simply take your first steps toward net-zero transport, CoolRun is now open for trials.